Technological innovation in industrial agitation

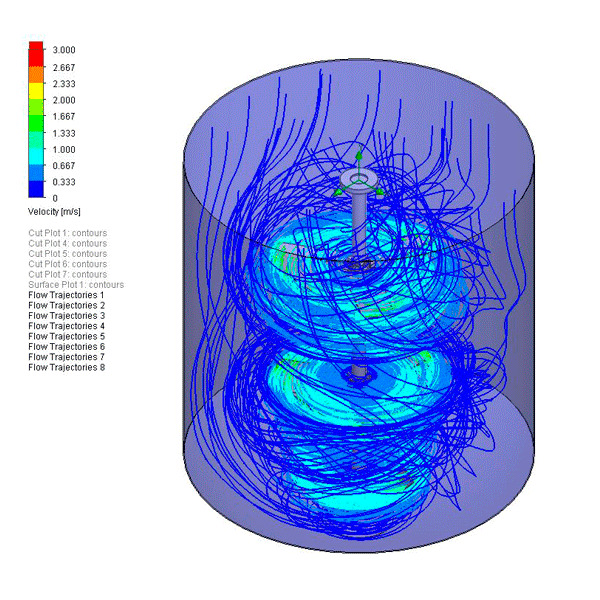

At InoxMIM, our commitment to innovation is reflected in the continuous research and development (R&D) of new agitation systems. Our engineers work on designing customized technologies, utilizing cutting-edge fluid simulation software and parametric systems. This enables us to offer equipment tailored to the specific needs of each client, maximizing operational efficiency and minimizing downtime.

As manufacturers of industrial agitators, we provide a wide range of equipment designed for various applications, from vertical and side-entry agitators to blenders, emulsifiers, and mixers, all adapted to meet the most demanding production conditions.

Our industrial agitators catalog

Discover our specialization in agitation, emulsion and blender solutions

Applications in different industrial sectors

As one of the leading manufacturers of industrial agitators, our solutions are present across a wide range of industrial sectors, delivering optimal results in every application:

- Food industry: In processes such as the production of sauces, dairy products, and beverages, InoxMIM agitators and mixers ensure perfect ingredient homogenization, optimizing both product consistency and process efficiency.

- Cosmetic and pharmaceutical industries: For the production of creams, lotions, gels, and medications, our agitators provide precise mixing that guarantees the quality and stability of the final products. Emulsifiers are essential in creating stable and homogeneous emulsions.

- Chemical industry: In the handling of chemicals and the mixing of corrosive or viscous substances, our solutions offer reliability and durability, ensuring process integrity at all times.

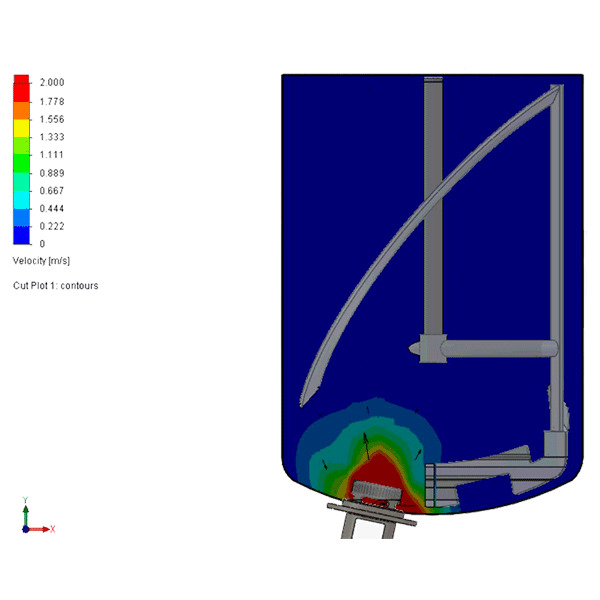

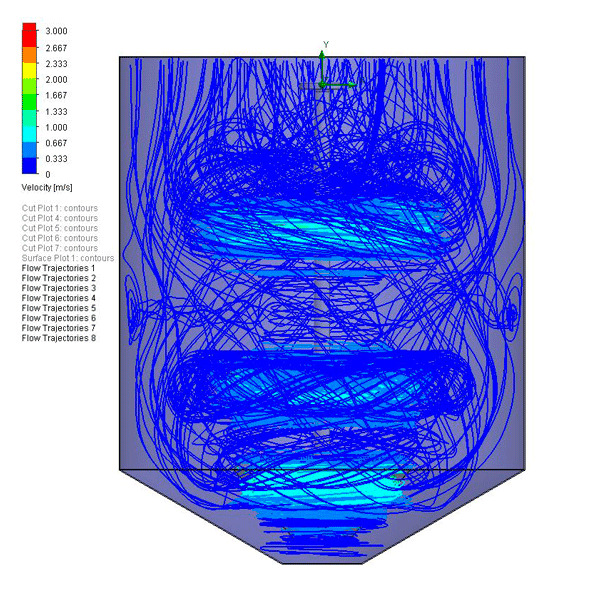

Simulations and advanced design of agitators

One of the key differentiators of InoxMIM as an industrial agitator manufacturer is our use of advanced simulations in equipment design. Thanks to our fluid simulation tools and parametric modeling software, we can ensure that each agitator is designed with precision, guaranteeing optimal performance based on the specific needs of each client. This allows our engineers to predict flow behavior, ensuring maximum efficiency and homogeneity in every process.

Commitment to quality and customization

Quality is one of the fundamental pillars at InoxMIM. All our agitators are manufactured with high-strength materials, such as stainless steel, and are designed to operate under the most demanding conditions, including applications that require agitation under vacuum or pressure. Additionally, each of our pieces of equipment can be customized to meet the specific requirements of our clients, ensuring that every production process is as efficient as possible.

Contact us for customized industrial agitation solutions

At InoxMIM, as manufacturers of industrial agitators, we understand that each company has unique needs. That is why we offer personalized advice and technical support to help you select the industrial agitator that best suits your processes. If you need more information about our agitator solutions, please do not hesitate to contact our team.