In this article, we show you what the NPSH of a centrifugal pump is, how it is calculated and the importance of knowing this parameter when you decide to buy one of our centrifugal pumps.

The NPSH of a centrifugal pump, definition:

This is the acronym for Net Positive Suction Head (ANPA). In practice, this is the parameter that helps us to determine the correct operation of a pump, without it entering into cavitation.

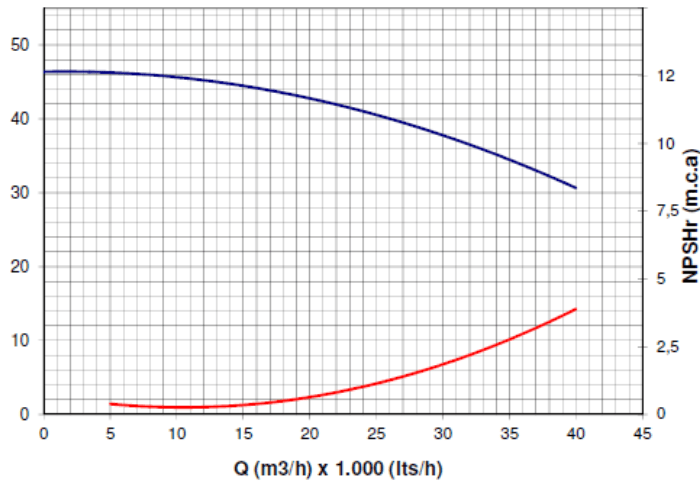

Thus, the best way to know if and to what degree this phenomenon, so negative for the useful life of the machine, is going to occur is by comparing the available NPSH parameters with the required NPSH.

The first is the minimum NPSH value necessary for the pump to avoid cavitation. This parameter varies according to the model of the device, so it is essential to check it in the technical documentation provided by the manufacturer with each item.

Another aspect to consider is the available NPSH, which depends on the characteristics of the circuit and also indicates the risk of cavitation. It varies according to the pressure drop in the suction circuit, the vapour pressure of the liquid and the suction head.

But what is cavitation, and why is it important to know about it?

Cavitation is a phenomenon that occurs when the pressure in a pipeline drops below the vapour pressure. At that moment, bubbles are formed that move with the liquid fluid through the pipeline to where there is more pressure and, in turn, condense, causing negative instability for the elements that share the pipeline.

If this phenomenon occurs, the pump material is weakened, leading to rust, vibration, noise, and even pitting, thus shortening the service life of the centrifugal pump.

Different degrees of cavitation can be detected: moderate cavitation, which allows a fluid to flow but with less flow than usual, reducing more or less drastically the performance of the centrifugal pump. Above that, there is the case of severe cavitation, which can totally affect the pumping capacity of the machine.

How to avoid cavitation in your centrifugal pump?

To avoid these problems, a ratio of 0.5 metres of safety must be complied with:

NPSHdisp (NPSHavailable) ≥ NPSHreq (NSPH required) + 0.5

In this equation, it must be considered that the NPSHreq value is only set by the pump’s factory characteristics. It is always positive and varies depending on engine speed and flow rate.

This value shows the suction capacity of a pump at a given point in its operation. In practice, we can say that the lower the NPSHreq value, the higher the pump’s suction capacity.

However, the NPSHdisp depends on the type of installation and is equivalent to the pressure reserve over the vapour pressure of the fluid and is something you have to calculate.

The NPSHdisp can be calculated using two formulas that analyse parameters such as suction lift, fluid density, pressure levels, gravity and vapour, among others. There are also automated calculators that do this study online by entering just a few parameters and can be found with a simple internet search.

In any case, if you would like us to help you, or if you would like to request information about one of our pumps, all you have to do is contact our sales department by calling (+34) 972 58 20 40 or writing to us at [email protected]. If you take a few seconds to browse our website, you will see that we also have a form that you can fill in with your details and one of our sales representatives will call you back immediately.