What types of heat treatment in food are most common?

Within the food industry, there are different types of treatments used in products distributed to consumers. Thus, great emphasis is placed on monitoring and supervising each of the processes, with the aim of delivering a delicious and pleasant product, while ensuring it is not toxic to health.

Therefore, we will now examine some of the most commonly used thermal treatments in the food sector to understand their main advantages and in what type of food they are usually employed.

Table of contents

Why is heat treatment necessary in food?

The application of heat treatments in the food industry is primarily aimed at destroying or eliminating enzymes or microorganisms that can alter the food (agents that can potentially cause diseases).

Other advantages offered by these treatments through the application of intense heat include:

However, it should be noted that if these types of treatments are not applied by experts, undesirable and unsatisfactory results may occur for the industry.

Related articles:

What types of heat treatments exist?

In particular, we will mention four types of heat treatments that are most commonly used in the industry and yield the best results. These are:

Blanching Treatment

This is a process used as a pre-treatment before other types of treatments. It is primarily used for vegetables and animals (although not all vegetables and fruits can be blanched). Its main purpose is:

Cooking Treatment

More commonly recognized as a technique applied directly in the culinary industry, cooking treatment can also help reduce microbial production to a certain extent. Its main objectives are:

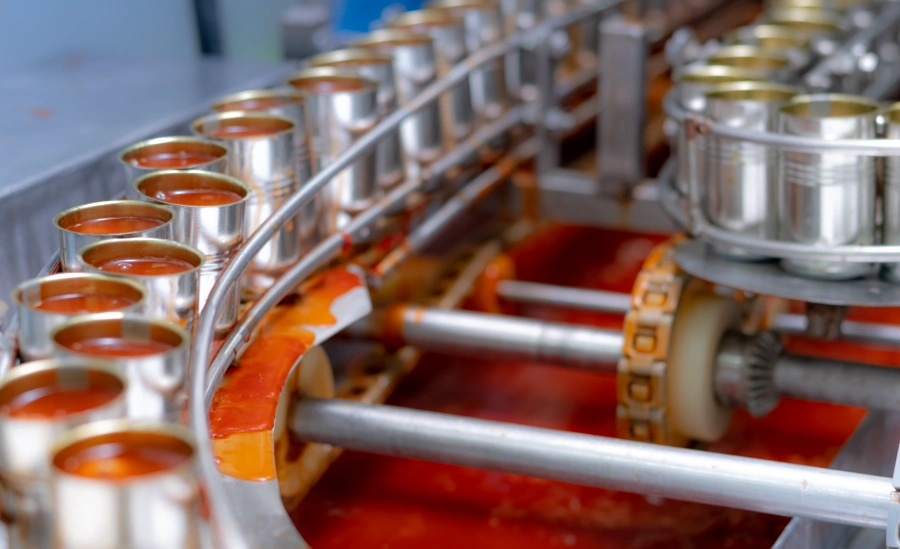

Pasteurization Treatment

Pasteurization is one of the oldest methods in the food industry and is one of the most effective treatment systems. Its main benefits include:

It is necessary to clarify that when applying pasteurization, certain calculations must be made (in terms of time and temperature) to avoid excessive exposure of the food, which could result in a loss of nutritional qualities.

Additionally, this type of treatment has specific objectives depending on the type of food. For highly acidic food, the goal is stabilization, while for low-acid food, the goal is pathogen destruction.

Automatic pasteurizer of 1000 liters

First, a thermal treatment is applied to generate a shock. In this way, chemical additives can be applied to extend the shelf life of the food and keep the product stable.

Meanwhile, you can opt for a batch process where the product is first packaged and then pasteurized, or in a continuous manner, first pasteurizing and then packaging (a decision that can affect the selection of the type of packaging).

Sterilization Treatment

If the goal is to subject food to high temperatures above 100°C for preservation and elimination of organisms, then heat treatment by sterilization is required. Its main objectives are:

The need for different technologies may arise depending on whether the food is packaged first and then sterilized or vice versa.

Process. The food is subjected to high temperatures for a specific time to ensure the elimination of harmful components. Additionally, a liquid, either water- or oil-based, can be used to cover the food to prevent damage in case of direct exposure to heat.

Conclusions on Types of Heat Treatment in Food

The food industry is closely monitored by authorities and autonomous organizations to ensure that what is produced is of high quality and nutritious. Using appropriate industrial tools is crucial to achieve desired outcomes for both the company and the consumer.

At InoxMIM, as experts in the development and manufacturing of machinery to improve and optimize processes in the food industry, we can greatly assist you in achieving the desired results. Simply contact us by phone at +33 1 58 20 40, send an email to inoxmim@inoxmim.com, or fill out the following form, and one of our sales technicians will get back to you shortly.

Contact us