The efficiency of a centrifugal pump plays a crucial role in the production processes of practically all industries. No matter what industry you’re in – be it food, pharmaceutical, cosmetic or chemical – the performance of your centrifugal pump can have a significant impact on the overall efficiency of your production.

A centrifugal pump that operates at its maximum level of efficiency not only guarantees smooth and constant production, but can also be a differential in terms of productivity and operating costs. . These machines, when they are working at their maximum performance, can increase the power of the productive units, optimize the use of energy and reduce downtime due to maintenance problems or breakdowns.

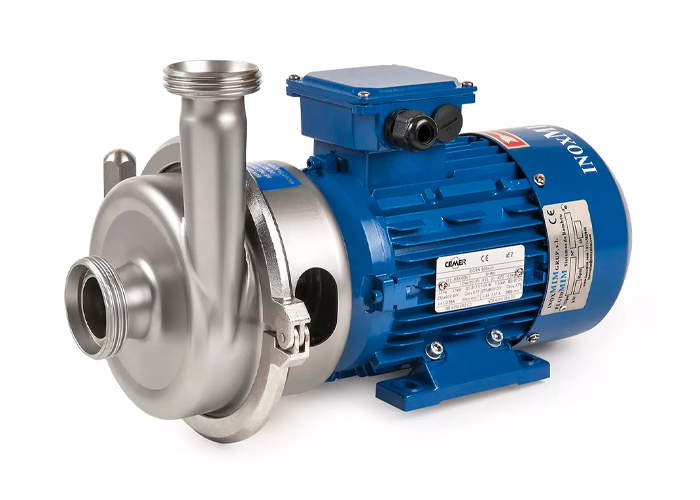

At InoxMIM, we are aware of the importance of efficient centrifugal pumps in modern industry. With decades of experience designing and manufacturing these devices, we are committed to providing pumping solutions that not only meet, but exceed performance expectations.

Our products are known for their durability, reliability, and optimal performance, making InoxMIM the preferred choice for various industries, including food, cosmetics, and chemicals, among others.

In this article, we will address the factors that contribute to the efficiency of a centrifugal pump. From choosing the right model to recommended maintenance practices, these aspects are critical to ensuring your centrifugal pump operates to its full potential.

In addition, we will present how InoxMIM products and services can help you maximize the efficiency of your centrifugal pump and consequently improve the productivity and profitability of your operations.

The function of the centrifugal pump within the production process

In the first instance, centrifugal pumps are in charge of transferring the liquid inside the industrial machinery for the generation of hydraulic energy. In this way, they are very important within any production process, so that the manufacture of goods does not depend exclusively on other, more expensive forms of energy.

Thus, this is not only a safe mechanism to generate energy, but it is more economical than other ways that demand more resources. However, centrifugal pumps may have other benefits that are different from those usually attributed to them.

In this context, these pumps can also be used to generate cooling, drainage and irrigation processes in industrial systems, which gives them wide versatility with high performance.

Therefore, a centrifugal pump will be truly efficient as long as it is used for the recommended uses, and under the safety parameters stipulated by the manufacturer and subsequent recommendations.

Regarding the latter, it is relevant to point out that industrial safety guarantees not only the integrity of centrifugal pumps, but also that of the rest of the components of the production system.

What factors determine the efficiency of a centrifugal pump?

In addition, considering the various applications that these devices have, it is crucial to highlight that centrifugal pumps can achieve high efficiency, both with conventional liquids and with other viscous materials, depending on the nature of the company that installs them.

However, its efficiency does not depend solely on the result of a simple physical formula, but the pre-established conditions in the industrial sector must be strictly complied with, so as not to cause accelerated wear of the pumps.

Consequently, by applying volumes that do not oversize the hydraulic conversion apparatus, a higher energy cost will be avoided in the operation of the pumps and, therefore, in their useful life.

What efficiency limits are handled in centrifugal pumps?

The usual limits of effectiveness in centrifugal pumps are estimated from 55%. However, the ideal parameter is to reach up to 94% efficient work on these devices.

This depends to a large extent on the industrial application for which the pumps are intended and the time elapsed after their installation, since the natural wear and tear of operation leads to a reduction in efficiency.

Therefore, centrifugal pumps must be properly certified for proper long-term operation so that companies have a reliability endorsement around their performance. The efficiency limits are duly corresponding to the quality controls to which these pumps are subjected.

Why choose InoxMIM centrifugal pumps?

Quality standards in the industry are what ensure that a device works correctly and is efficient. This is mainly the reason why we stand out at InoxMIM, since as one of the most efficient centrifugal pump manufacturers in Spain and through FLUIDMIM, we have the best qualified engineers to achieve the highest performance quotas in the market.

With ISO validations and quality certificates from Spain, our centrifugal pumps are guaranteed to be an efficient device that meets the respective operating and safety conditions. And this can be corroborated not only with our efficient centrifugal pumps, but also with the rest of the industrial implements that we design and manufacture.

Under this premise, at InoxMIM we have strict control in the development of our centrifugal pumps, so that our customers can obtain the best products, at an excellent price and with the features that this type of high-calibre device must have.

Whether for the food, cosmetic or chemical industry, our centrifugal pumps provide high efficiency in fluid handling and the energy transformation that your company requires. If you have any questions, you can call us at +34 972 58 20 40, or write to our email inoxmim@inoxmim.com.