Industrial equipment for production of dairy products

InoxMIM, as a leader in innovation and technological development, offers a range of industrial equipment for dairy product processing that is at the forefront of the market. We are dedicated to supplying high-precision equipment and designing fully automated industrial installations for the production of a variety of dairy products, such as yogurts, creams, cheeses, shakes, and desserts, among others.

Our comprehensive approach allows our customers to significantly increase their production while ensuring the highest food safety standards demanded by this industry.

We aim not only to meet our clients’ current needs, but also to anticipate future challenges in the sector by providing scalable and flexible solutions.

At InoxMIM, we are characterized by our unwavering commitment to excellence and quality. Our advanced management systems and state-of-the-art software are at the core of our operations, enabling our technical team to ensure the effectiveness, reliability, and efficiency of every piece of equipment we develop. We are aware of the importance of every detail and work to eliminate any possibility of error.

This is why we offer our pilot plants. In them, our clients can conduct scale tests, allowing for an in-depth study of the feasibility of each product before making crucial decisions or implementing large-scale changes. This service reflects our proactive approach and our desire to provide peace of mind and confidence to our clients at every phase of the project.

We firmly believe in finding the optimal solution for every situation and client. Therefore, our work process includes a thorough analysis of the specific needs and objectives of each project, enabling us to design completely customized and highly effective solutions. Our respect for our clients and their vision motivates us to continue innovating and perfecting every aspect of our services and products.

Our dedication to continuous improvement and our deep knowledge of the dairy industry position us as the ideal strategic partner for any company looking to increase its production capacity and competitiveness in the market. At InoxMIM, every client is a valuable ally, and our mission is to contribute to their success and sustainable growth.

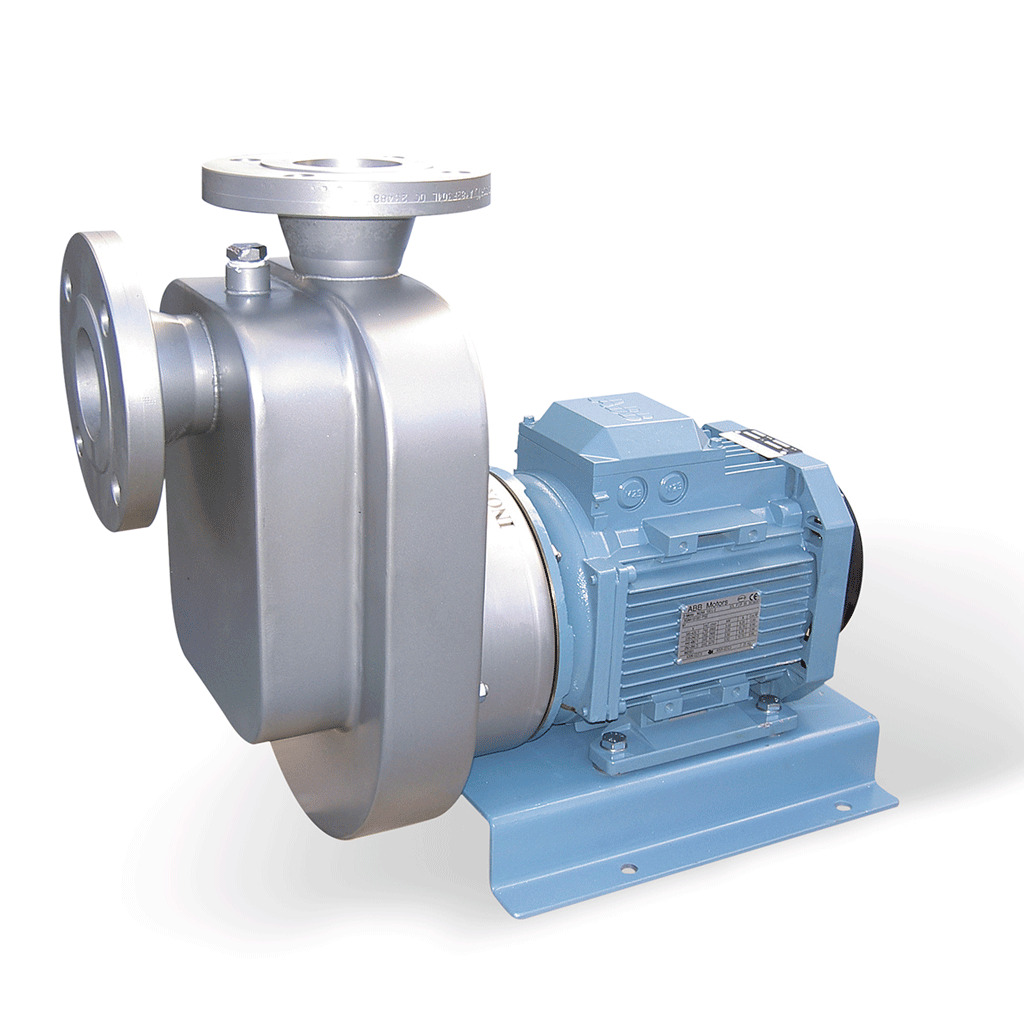

Automatic pasteurization equipment for

large volumes

Multiproduct electric pasteurizer

What dairy product processing equipment can we provide you with?

One of InoxMIM’s specialties is the manufacture and design of special machinery for the industrial production of pasteurized foods using the HTST-HIGH Temperature Short Time system. We can offer you autonomous electrical equipment, heat and cold generation systems, to work with both small and large quantities of any liquid… The possibilities are many!

But it’s important to emphasize that our proposals include autonomous electrical equipment and integrated systems for heat and cold generation, ready to handle various production volumes and different types of liquids. We also offer customized solutions tailored to the needs and objectives of each client, ensuring seamless integration with their existing operations.

Other related articles that might interest you:

Still have questions about it? Contact us!

The food industry is full of challenges and critical decisions. At InoxMIM, we understand the importance of having accurate information and expert guidance. Our team of specialized engineers and technicians is at your disposal to answer any questions and provide the necessary support in every phase of your project. You can inquire without any commitment through our contact form or by calling 972 58 20 40.

In a world where technology and innovation are fundamental pillars, InoxMIM leads the way in developing solutions for dairy product manufacturing. Every piece of equipment we design reflects our commitment to excellence, quality, and customer service. If you’re looking for a partner who understands your challenges and helps you achieve your goals, InoxMIM is the right choice. Together, we will build the future of the dairy industry!