Our wide range of industrial liquid agitators is specially designed for the agitation of dosing tanks, dispersion of reagents, maintenance of mixtures and dissolution of solid products.

InoxMIM industrial liquid agitators are developed by our engineering department. Since its inception, our agitation department has been a benchmark in the field of vertical agitation. We have a wide variety of sizes and models, which, together with the optimized and customized designs that we usually offer our customers, make each agitator able to adapt to a wide variety of applications.

Table of contents

- Vertical industrial agitators for the cosmetics industry

- MD and MDN Industrial Liquid Agitator

- Industrial liquid agitator SB, SBR and SBN

- Industrial liquid agitator VAI, VSI, VDI and VSIN

- VMD and VMR industrial liquid agitator

- IBC Industrial Liquid Agitator

- Industrial liquid agitator VCI and VCIN

- GFL/GFLE Industrial Liquid Agitator

- TANDEM industrial liquid agitator

- Industrial side agitators for the cosmetics industry

Vertical industrial agitators for the cosmetics industry

InoxMIM vertical agitators can cover the different needs of each industry due to their special characteristics and configurations that adapt to the needs of our customers who belong to the cosmetic industry sector.+

Its price is tight, but its performance is great, as well as its reliability and little need for maintenance. Our agitators are the best choice for a good result. In InoxMIM, it has several models.

MD and MDN Industrial Liquid Agitator

MD and MDN liquid agitators have been designed for the preparation of reagents in small or medium-sized tanks.

The versatility that the agitation components bring to this equipment allows a great adaptation to any type of manufacture. The high speed at which the drive element can reach makes them ideal for dilutions, dissolutions, and homogenizations.

Industrial liquid agitator SB, SBR and SBN

These SB, SBR and SBN agitators provide a high degree of agitation in small volume tanks. Thanks to their compact design and simple jaw anchoring system, they are ideal for agitation in tanks that need to be open, for dispersion of reagents, dispersion of powders and maintenance of mixtures, as is the case in the cosmetics sector.

Industrial liquid agitator VAI, VSI, VDI and VSIN

The industrial liquid agitator models VAI, VSI, VDI and VSIN are perfect for the preparation of reagents, such as those used in the cosmetic industry. The turret is made of aluminium, and the other parts are made of AISI 304 stainless steel.

They have a sealing system that provides a great capacity for agitation and exceptional performance thanks to its effort turret and semi-axis transmission system.

On the other hand, the level of finish of its design has been designed so that its use is safe, and its simple sanitation, thus facilitating maintenance tasks and optimizing cleaning tasks.

VMD and VMR industrial liquid agitator

The characteristics of VMD and VMR industrial agitator designs allow a wide variety of impeller elements to be used. They can work with highly viscous products, with a tendency to form lumps or difficult to mix and are capable of performing a wide variety of processes such as solutions, solutions, mixtures of reagents, etc.

IBC Industrial Liquid Agitator

The IBC vertical agitator has a coaxial geared motor. Thanks to the different sizes and types of propeller that can be used, in addition to the motor system with coaxial reduction that allows a wide range of speeds, it makes it a versatile industrial liquid agitator.

Industrial liquid agitator VCI and VCIN

The VCI and VCIN liquid agitators are equipped with an auger screw motor reducer together with a seal sealing system. This allows the use of large blade surface impeller elements, achieving a high agitation performance. In the case of the cosmetic industry, it is useful for mixing, maintaining and homogenizing products or suspensions.

GFL/GFLE Industrial Liquid Agitator

They are driven by a geared motor that works with parallel gears. The rotation works at low speeds and thus allows the use of agitator elements with a large blade surface and a high working performance. The GFL and GFLE agitator models are essential equipment in the cosmetics industry.

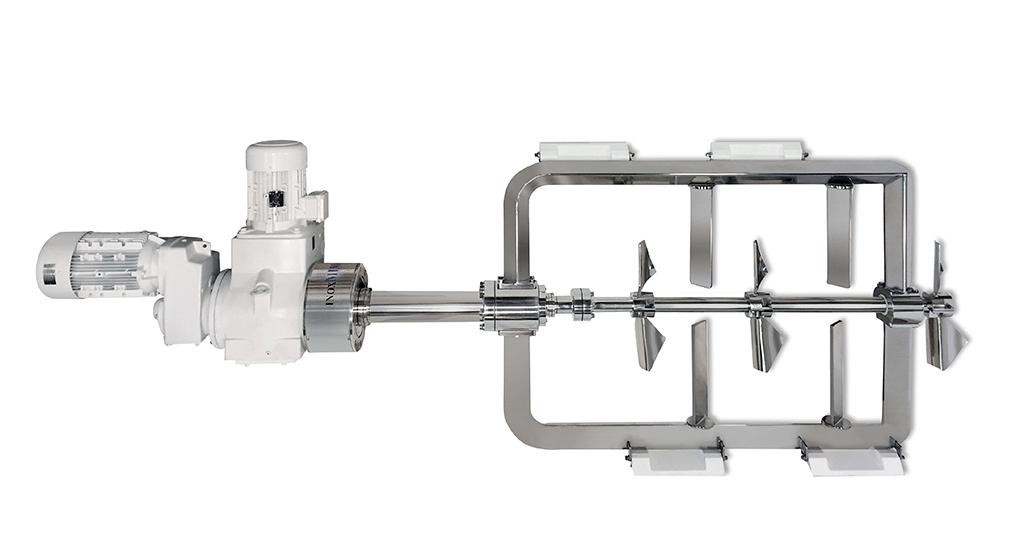

TANDEM industrial liquid agitator

TANDEM agitators are perfectly adapted to the requirements of the cosmetic industry. They have a wide range of applicability and a great capacity for agitation, which is due to the multiple configurations of the impeller elements available, and which makes them fully adaptable to each system.

Industrial side agitators for the cosmetics industry

These are essential equipment for the good homogenization and maintenance of the products. In InoxMIM we have several models of side agitators designed to cover the degree of agitation required in each industrial process, although all depending on the capacity of the tank and the product to be shaken.

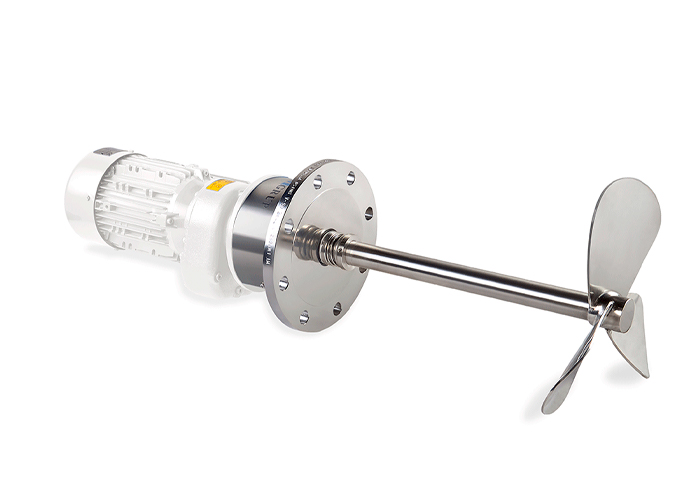

LMDS Lateral Industrial Liquid Agitator

The LMDS model is a side agitator with direct motor and guide tower. Thanks to the simplicity of its parts together with the mechanical sealing system, it offers optimal mixing capacity in a wide variety of processes. That is why LMDS side agitators are high performance and, in addition, economical.

LMD/LECO Lateral Industrial Liquid Agitator

Both the LMD and the LECO model are installed in the lower part of the tank with the appropriate inclination to obtain the optimal mixing regime. With this same objective, both the shaft length, the diameter, and the type of propeller are selected.

Choose InoxMIM as your trusted industrial agitator manufacturers

As in all our production equipment, we adapt to the needs of each client, so do not hesitate to ask for a quote without obligation, whether you need an agitator for the cosmetic industry or an agitator for the food industry.

You can contact InoxMIM by calling +34 972 58 20 40 or, if you prefer, write to us at [email protected]. It will be a pleasure to help you choose the right industrial liquid agitator for your cosmetics industry.