What is a food processing plant?

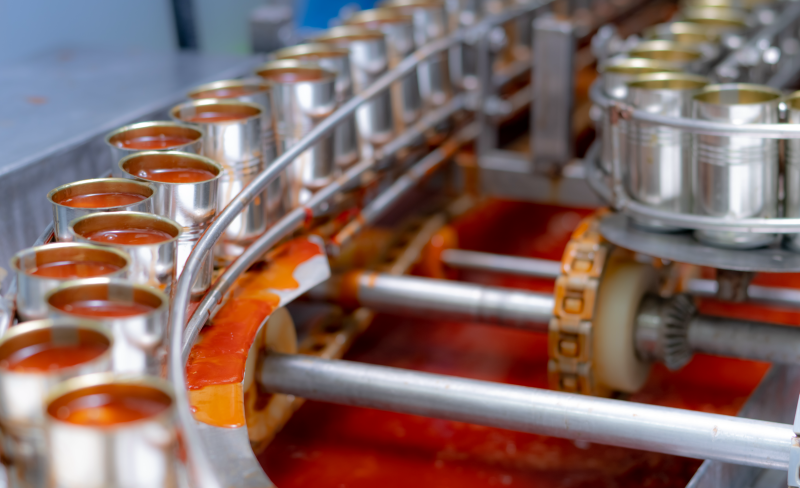

A food processing plant is a critical infrastructure employing state-of-the-art technology and advanced industrial machinery.

It is specifically designed to meet stringent food hygiene and safety standards, ensuring the mass production of safe, high-quality food.

This type of facility operates under strict principles, from the handling of raw materials to the distribution processes, guaranteeing compliance with legal requirements and those of consumers in Mexico and South American countries.

The importance of having adequate space, both in terms of size and sanitary conditions, is fundamental to adapt to the quality standards and regulations of today’s market.

In this context, comprehensive management and careful control at each stage of the food transformation process are essential to maintain the integrity of the product, from its initial conception until it reaches the consumer’s hands, thus ensuring food safety and customer satisfaction.

Quality control in food processing plants

Quality controls in food processing plants are essential to ensure safe and high-quality products. These controls, in countries such as Mexico and Brazil, comprise a meticulous process divided into phases: positioning, identification, verification, measurement and detection of defects.

In addition, they evaluate sensory properties such as flavor, color, aroma and texture, ensuring that the food complies with legal regulations on composition, packaging and shelf life. This process is vital to protect the consumer, maintaining quality and food safety standards.

On the other hand, it is important to note that these controls are fundamental in the food production chain, where each phase is critical to ensure that the final products are safe and comply with all relevant regulations. In addition to the aforementioned phases, this integral process also includes product traceability, supplier management and continuous evaluation of internal processes.

This guarantees complete oversight from raw material to final product, ensuring that every element meets the highest standards of quality and food safety, adapting to legal requirements and consumer expectations. This holistic approach is essential to prevent health risks and strengthen trust in food brands.

As a leading supplier of machinery for the entire South American market, we know everything you need to know about industrial food production.

We can advise you with the design of your food processing plant; inform and advise you with legal and quality control issues; or supply you with state-of-the-art equipment and tools for large-scale food processing.

We have industrial solutions for medium and large liquid and semi-liquid food products.

Related articles:

Vertical agitators for the food industry:

CIP cleaning equipment to ensure the highest level of hygiene and disinfection in every industrial process

CIP equipment is very common in the food industry, as it offers a high degree of hygiene and disinfection for all machinery and facilities in which food is produced industrially.

For example, this is one of the most effective methods for eliminating biofilms; these are a layer of proteins that form and cover microbes in long industrial production circuits with many elbows.

They are a very invasive type of microbiological contamination and can cause you a lot of headaches if the disinfection process is not carried out correctly.

In InoxMIM we have a high degree of specialization in everything related to the design, manufacture and installation of these sanitizing equipment, being able to advise you and solve all the doubts you may have about its operation.

These equipments work taking into account four factors: the mechanical factor, the time, the temperature and the detergent. In today’s production plants there are two different types of dirt: organic dirt, remains of fats and proteins, and mineral dirt, precipitations of Mg, Ca and other chemical elements.

Alkaline products, acids and disinfectants are used for their elimination. For organic dirt, soda and KOH are used, which act by saponifying the fatty matter and hydrolyzing the proteins.

Chlorinated alkaline products are also used for disinfecting and bleaching. As regards acid products, nitric acid and phosphoric acid are responsible for neutralizing mineral precipitations such as Ca or Mg.

And we finish with disinfectants such as ammoniums or aldehydes, which are usually used to rinse and finish the disinfection completely.

Do not hesitate to ask us for information about these equipments; just take a few seconds to fill in the following form, and you will hear from one of our commercial technicians in a short period of time.