Discover all the special features of our industrial emulsifiers

At InoxMIM, you will find the ideal industrial emulsifier to meet your needs, as we are dedicated to manufacturing this equipment for different applications and sectors. The industrial emulsifiers are designed to meet all the requirements in dispersion, emulsion and grinding processes of the product.

We have extensive experience in the manufacture of industrial machinery and in the marketing of emulsion systems for the cosmetics, pharmaceutical, and food industries. For this reason, we have 3 different varieties of industrial emulsifiers: vertical, in-line or bottom emulsifiers. Their installation will also depend on the dimensions of the tank, the characteristics of the product you are going to work with or the production methodology you use.

What types of industrial emulsifier does InoxMIM offer?

Vertical emulsifier EM

These emulsifiers are the best option when bottom space is not available. They are designed to work in smaller tanks, where no precipitation-prone components are added and do not require a lot of additional agitation.

There are two types of emulsifiers in our catalogue. One of them is the EM vertical emulsifier, which provides high shear rates in emulsions and dispersions thanks to the design of the heads and turbines, which also allows maintaining a remarkable hygiene and to speed up maintenance tasks.

With the EM vertical emulsifier, as with other mixers of this type, you will obtain a completely homogeneous and lump-free product in processes with medium (5,000 litres) and small volumes. It is also useful in the maintenance of already homogenized products, preserving their properties.

The head is selected according to the product and its requirements, and can be sieved, slotted or perforated. This is why this equipment is capable of reducing particle size, eliminating agglomerations and quickly dissolving solids in liquids, allowing for homogeneity.

Vertical emulsifier EMV

The other type of vertical emulsifier we can offer you is the EMV model. This emulsifier is developed for the difficult mixing of products, whose head is adapted to each application, improving its performance and optimizing the operation time.

You can find this vertical emulsifier EMV 1-stage and 2-stage (EMVT), allowing both designs to obtain emulsions and dispersions that require a high degree of shear.

Likewise, this equipment has the capacity to work with high viscosity products (up to 20,000 cP) obtaining a completely homogeneous result. In the same way, its sealing system allows the work to be carried out in non-atmospheric conditions (overpressure or vacuum) without the need for an external refrigerated mechanical seal.

Like the previous vertical emulsifier, the design of this one also makes it possible to maintain a remarkable hygiene which, together with its simplicity, facilitates maintenance tasks.

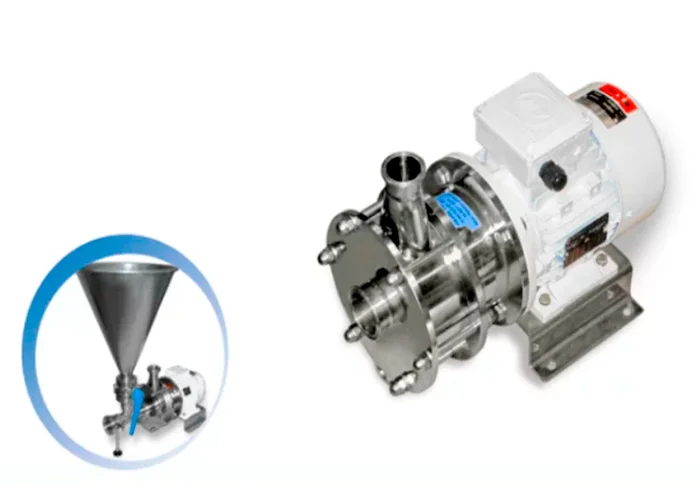

In-line emulsifier EML / EMLT

The EML/EMLT in-line emulsifiers can be used to work with recirculation: taking the product back to the reactor or as a final conditioning stage of the pre-packaged product. In addition, they provide high emulsification and pumping of the product, thanks to the innovative design of the heads and impeller turbines.

On the other hand, they facilitate the use of multi-toothed heads for shearing the product, together with a minimization of production time, obtaining a completely homogeneous result, without lumps and avoiding oxidation. Furthermore, the in-line emulsifiers are useful in the transfer and handling of already homogenized products, providing a careful treatment of the product and maintaining its properties.

Bottom emulsifier

Finally, you will also find in our catalogue an industrial bottom emulsifier whose location favours the preparation, for example, of cosmetic products with a high load of solids and viscosity.

At InoxMIM you will find a wide range of bottom emulsifiers, ideal for working in processes of dispersion, emulsification, homogenization, and grinding of the product.

These bottom emulsifiers for EMF tanks are installed in the lower part of the tank, allowing the rapid dissolution of the heaviest product particles. The rotation of the turbine allows the necessary suction and suction of the fluid towards the centre of the head where, thanks to the centrifugal force, it is directed towards the outside. Once the space between the turbine and the stator is reached, the pressure of the product rises and the grinding process begins.

Subsequently, when passing through the orifices of the head, the high rotational speed generates a very high shear force, resulting in the dispersion, emulsification, and total homogenization of the mixture, and this process is constantly repeated.

These bottom emulsifiers can be complemented with a pumping body (EMFL), allowing the same equipment installed at the bottom to pump the product back into the tank, thus optimizing the mixing time. In addition, the smaller cleaning surface area greatly simplifies sanitizing tasks. Blades can also be incorporated to pre-sieve solid products before they enter the rotor-stator and reduce the preparation time for vegetable creams, smoothies, purées and sauces.

Get the best industrial emulsifier for your company at INOXMIM!

If you are interested in any of our industrial emulsifier models, just contact INOXMIM. Our sales department will advise you on the model you should choose to optimize your production to the maximum. Your satisfaction is our main objective. Call us on +34 972 58 20 40 or write to us at [email protected]. Get the best industrial emulsifier at INOXMIM!