Everything you need to know about InoxMIM’s side-entry agitation

The majority of companies that work with liquids have reagents or products that must be constantly kept in motion for optimum conservation. The intention behind this is to constantly preserve both the product’s properties and homogeneity.

It is crucial to use a side-entry agitator to carry out this process properly, except in cases with a high-viscosity product.

What is a side-entry agitator?

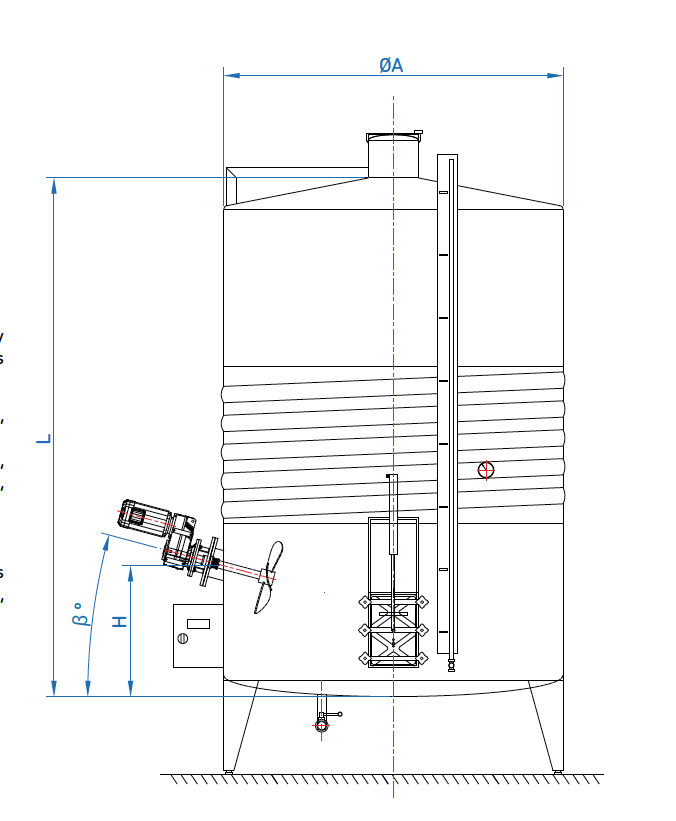

A side-entry or bottom-entry agitator is a compact version of a vertical agitator, specially designed to maintain smooth movement in tanks of a certain size. They are ideal for when there is limited space at the top of the reactor or when there is not sufficient tank depth to accommodate a large vertical agitator.

Most common applications for the side-entry agitator

The key to operating a side-entry

The secrets to its successful operation lie in the design of the propellers, the speed of rotation and, above all, the correct angle and position of installation in relation to the bottom of the tank. If anything fails, it is a bad installation.

So, what are the possible consequences of a bad installation?

You can rely on our technical department (AGITMIM) to ensure that everything runs smoothly

If you have any questions or need any advice, we have a department called AGITMIM, which is full of skilled technicians. A group of highly qualified professionals who will take care of the entire installation process, so you can avoid all the headache. By choosing InoxMIM you are choosing peace of mind, knowing you are in the best hands.