Industrial mixing is the mechanical process of forcing the movement of two or more fluids into a homogenized mixture of its components. In turn, such agitation can cause chemical reactions as well as thermal and mass transfers.

What elements are required to achieve the best possible industrial mixing?

To perfect industrial mixing, you must have specialized machinery. When you carrying out this process on a large scale you must take into account all the factors that are necessary to design and measure which equipment will handle the operation achieving the best possible results.

Selecting the right elements for the machine is important to avoid acquiring units with insufficient or excessive agitation. Both cost and consumption must not be high and long-term safety must be ensured.

At INOXMIM we develop mixing systems by selecting the best possible design that provides the mixing process required for a product. We offer diverse solutions in terms of agitation and mixing machines that guarantee a good seal, avoiding any leakage of the product, gases and other elements.

Our extensive experience and knowledge allow us to manufacture industrial mixing machines that can work under overpressure, vacuum and explosive atmospheres, using management systems and state-of-the-art software with parametric and fluid simulation programs.

What elements do we need for industrial mixing?

To understand how industrial mixing works, we must first identify the types of mixes between fluids. These can be miscible, easy to mix and form a homogeneous solution, or immiscible, with elements that have separate phases making it difficult to blend.

This is where the mixtures between liquids and solids appear, in which the particles of the latter need to be shaken mechanically for a certain period of time in order to dissolve and form a conglomeration. The other case is the merging of a liquid and a gas, where the second element, of smaller volume, is used as a support for agitation.

Our catalog of agitators for the food industry

Types of industrial mixers

Homogenization

Obtain a homogeneous mixture from two or more different non-homogeneous parts to obtain a mixture with the same properties in all substances. To do this requires relatively slow industrial mixers with axial flow turbines with a large diameter.

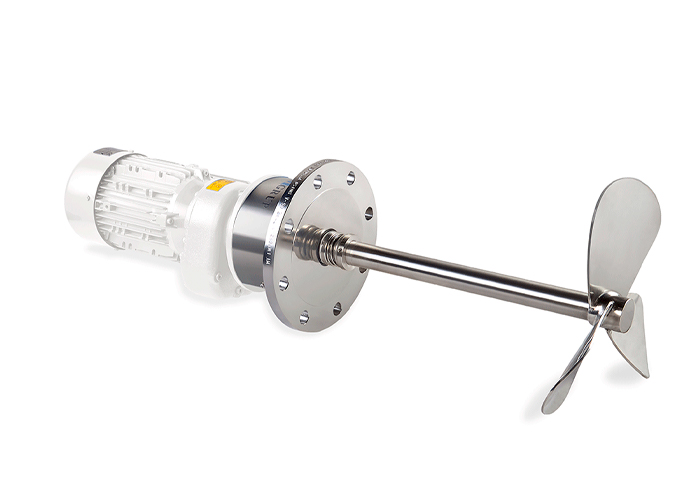

The LECOR/LMRE Lateral Agitators by INOXMIM, with motor-reducer, are a great example because these machines are designed to obtain a high degree of homogenization of the mixture making them widely used in the food industry, especially in the dairy sector.

Suspension

It’s the heterogeneous mixture made from a solid dispersing in a liquid. It’s possible to calculate the capacity of the agitator and its variant is determined in relation to the density and viscosity of the fluid together with the concentration and particles that make up the solid element.

In this case, at INOXMIM we recommend a BLENDER EMTB industrial agitator, a machine specially designed to incorporate solid food into a liquid base using the centrifugal force generated by its impeller.

We recommend this purchase when you are going to incorporate a large amount of solids either granulated or powdered in a base liquid during the manufacturing process.

Gasification

This is the essential agitation for the gas to distribute in the liquid. It requires the industrial agitator to perform the maximum interfacial area for chemical reactions by means of an intense level of agitation.

Related articles:

Dispersion

This process is done by mixing two immiscible liquids. For this, several processes must be used. Extraction, preparation of emulsions and proliferation, either in suspension or by emulsion.

The EMVT Emulsifiers were created and developed to mix products with complex components. They have a head designed to adapt to each operation improving its performance and optimizing the processing time.

The performance of this machine allows you to work with products that have high viscosities obtaining a totally homogeneous result.

Heat transmission

Agitation produces the confrontation or heating of the product contained in the tank to maintain temperature homogeneity throughout the product.

This is done to achieve higher transmission rates, thus saving technical exchange area that is not achieved in the same way with natural convection.

Fermentation

In this specific case, mixing ensures the homogeneous suspension of microorganisms in the medium containing nutrients. This biological process, assisted by industrial mechanics, allows temperature and PH control, and to incorporate oxygen in the case of aerobic fermentation or to eliminate gases formed in anaerobic ones.

For this type of process, here at INOXMIM we consider the LV Oenological Agitator ideal. It’s assembled to the ball valve of the tank, the shaft is introduced into the tank and activated by simply pressing the stop/go switch. It’s designed as a portable model for small tanks and is widely used in the wine industry both for its performance and its results coupled with its portability.

Crystallization

It’s used to purify a solid substance. Crystallization agitation should be energetic enough to keep the crystals in suspension while still taking into account that it should be soft enough not to break the crystals.

Hydrogenation

The entry of hydrogen by means of industrial agitation can be carried out externally through the shaft taking advantage of the suction of the turbine designed for that purpose.

The importance of having the right machinery to industrially agitate your product

All these chemical processes are taken into account by INOXMIM’s technical department to develop increasingly complex industrial agitation systems. The wide range of products we offer allows us to provide solutions in the handling and mixing of fluids in the vast majority of industrial, food, chemical, pharmaceutical and cosmetic applications.

If you would like more information, just contact our sales department by calling +34 972 58 20 40, sending an email to the address inoxmim@inoxmim.com or taking a few seconds to fill out this form.