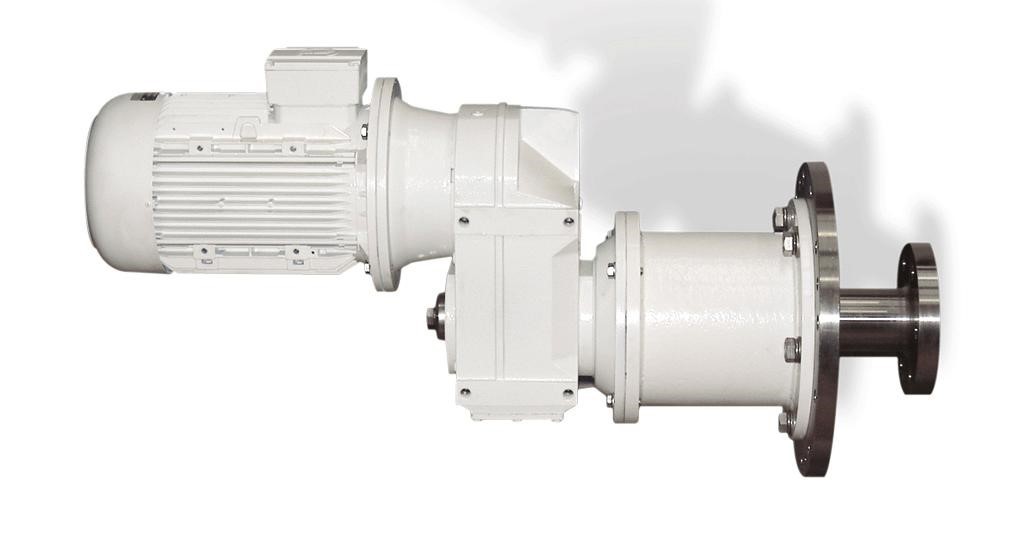

The GFL agitator: designed to provide the best results in an industrial chemical reactor

The GFL agitator is one of the most comprehensive in the InoxMIM catalogue. The combination of various seals and propellers facilitates adaptation to different industrial chemical reactor tanks, ranging between 50 and 500,000 litres in capacity. These agitators are defined by their broad applicability and their exceptional agitation capacity, featuring multiple drive element configurations, which allow for adaptation to the requirements of each individual system. As a result, they are indispensable for the food, pharmaceutical, cosmetic and chemical industries.

Applications of GFL agitators in different industrial sectors

In the food sector they can be used to make all kinds of dairy desserts, liqueur cream, juices, gazpacho…

The most common applications within the pharmaceutical industry are homogenisation, temperature exchange, mixing and suspension for tablets, solutions or creams. Finally, we would also like to point out that as far as the chemical sector is concerned, they are usually used for homogenisation and agitation of medium and high volume tanks.

If you want to receive more detailed information or need advice on which agitator is best suited for your industrial requirements, do not hesitate to contact our sales department. Simply click on the link at the end of this post and fill in the form. We aim to respond as soon as possible so we can provide you with the optimum agitation and mixing options for your facility or production line. Don’t waste any more time!