Industrial emulsion models and systems designed by our technicians

As a cosmetic machine manufacturer, in this post we would like to identify the differences between the different models and systems of industrial emulsion for cosmetic creams that we manufacture and market at InoxMIM.

There are three types of emulsion systems for manufacturing these products; they can be installed depending on the size of the tank, the product characteristics, or the production methodology used.

Emulsifiers for cosmetic creams

They are usually combined with a fairly complex agitation system, depending on the tank and products.

Vertical emulsifier for cosmetic creams

We strongly recommend a vertical emulsifier if there is not much space at the bottom of the tank. This usually applies to smaller tanks; likewise, it’s useful when we are manufacturing light creams that do not contain deposit-prone components and that do not require a high degree of additional agitation.

In-line emulsifier for the cosmetic industry EML

Installing an in-line emulsifier is another option when there is not enough room in the tank.

This equipment can be used for preparation by recirculating the product back to the reactor; or as a final phase of product conditioning after packaging. Its position facilitates joint operation with a positive displacement pump, in the event of more viscous procedures.

It also facilitates the use of multi-toothed heads for greater product shearing, along with a considerable production time reduction.

Cosmetic reactor with in-line emulsifier for product recirculation and release.

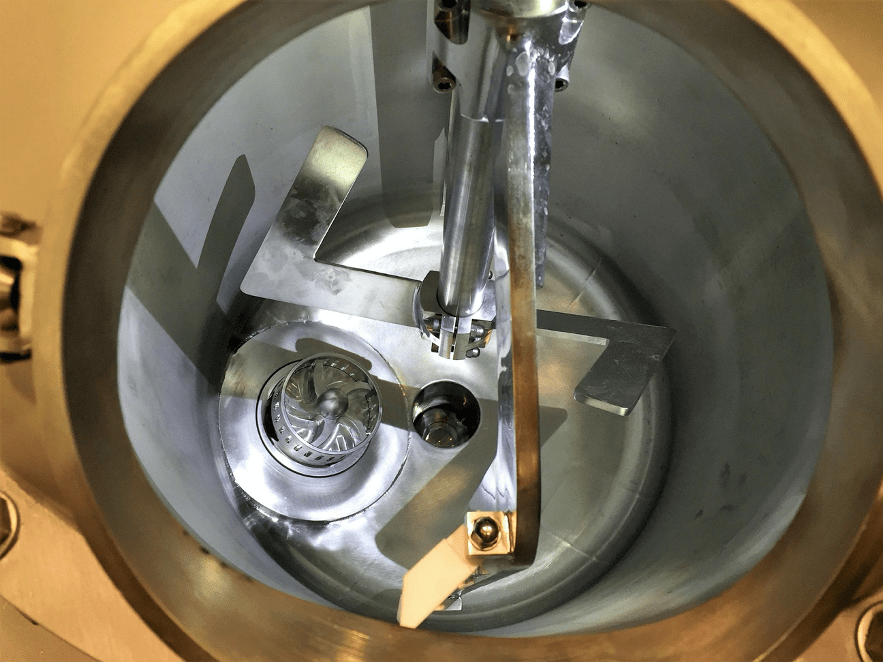

Bottom-entry emulsifiers

Finally, there are the bottom-entry emulsifiers. These are used to produce cosmetic creams, since their positioning facilitates production of products with a high solid and viscosity load.

Moreover, they tend to have a smaller cleaning surface, which substantially simplifies sanitisation.

Please note that this equipment can be combined with a pump body (EMFL), which allows the same unit installed at the bottom to pump the product back into the tank, thus optimising the mixing time.

It is important to note that a hopper can be incorporated into the vacuum reactors to suck the solids directly onto the rotor-stator, facilitating their integration.

Request non-binding information about our industrial cream emulsifiers

As manufacturers of machines and emulsifiers for various industrial sectors, we understand that this equipment is a major investment and often raises certain doubts or questions when you are not fully familiar with its applications.

If you would like direct and more tailored assistance, just give us a call on (+34) 972 58 20 40, send an email to [email protected] or fill out the form on this website.

Since its inception in 1997, INOXMIM has been strongly linked to the development and manufacturing of industrial machinery. The pumping, agitation, mixing, and fluid handling systems manufactured have met the needs of our clients throughout these years.

Continuous innovation and development enable INOXMIM to provide complete solutions in most processes, thereby meeting the most demanding requirements in the industry.

We are professionals with a long history and experience that backs us up.