What is an industrial agitator?

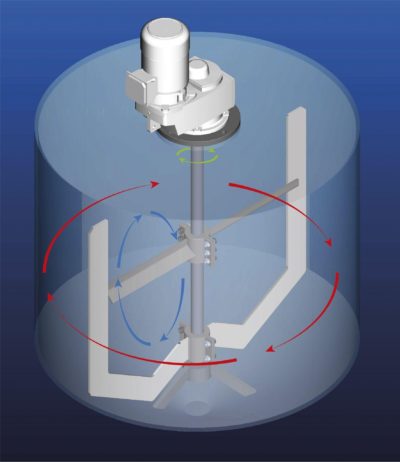

An industrial agitator is a tool that relies on agitation to mix low-intensity liquids or solids added to a mixture.

The main functions of industrial agitators can be maintenance, homogenization, heat exchange, dissolution, or dispersion.

Industrial agitator characteristics

Nowadays exists various types of agitators with different features. One of the most common ways of grouping them is as follows:

Turbine type industrial agitators

Industrial turbine-type agitators are recognized for their ability to produce a high radial flow. This feature makes them particularly effective for a wide range of mixing applications, especially in processes involving the handling of liquids or gases with varied viscosities, as well as in fluid reactions.

Their optimized design allows these agitators to efficiently handle low to medium viscosity liquids, ensuring a homogeneous and uniform mixing. This is crucial in industries where consistency and the quality of the final product are paramount.

Furthermore, their ability to generate a strong radial flow makes them suitable for processes that require intensive and rapid mixing, thus minimizing production times.

Propeller-type industrial agitators

Industrial propeller-type agitators stand out for their high performance in simple mixing tasks, being an efficient and reliable solution for a variety of industrial applications.

These agitators are specifically designed for mixing fluids of medium and low viscosity, an essential function in numerous industrial processes.

One of the main advantages of propeller-type agitators is their ability to significantly improve the uniformity of mixes.

This is achieved through its optimized design, which allows for efficient and consistent circulation of the fluid, ensuring that all components are mixed uniformly. This feature is particularly valuable in applications where product consistency is critical, such as in the food, cosmetic, and pharmaceutical industries.

Paddle type industrial agitators

Industrial paddle-type agitators are characterized by their simple and effective structure, making them an ideal choice for applications that require a uniform laminar flow. This type of agitator is particularly suitable for operations that need powerful mixing at low speeds, a crucial feature in certain industrial processes.

The main strength of paddle agitators lies in their ability to generate a smooth and consistent flow, avoiding the formation of vortices or dead zones within the mixing tank.

This is especially important in processes where the physical characteristics of the fluid must be maintained, such as in the mixing of suspensions or delicate solutions.

Moreover, paddle-type agitators are excellent for mixing materials with different densities and properties, ensuring a uniform distribution of components throughout the tank volume. This efficiency makes them ideal for applications in the chemical, food, and water treatment industries, where the homogeneity of the mixture is a critical factor.

Another significant advantage of paddle agitators is their robust and low-maintenance design. Their simple construction not only facilitates installation and operation but also reduces long-term maintenance costs, making them a cost-effective and durable investment for any industrial plant.

Some videos that might interest you:

Related articles:

Best models of industrial agitators

Highly efficient industrial agitators are manufactured and distributed in Spain. For example, in our company, INOXMIM, we manufacture high-quality agitators for the food, cosmetics and pharmaceutical industries, capable of adapting completely to the needs of all these industries. Some of our main models:

MD/MDN Vertical Stirrers

MD/MDN Vertical Stirrers are basic, very compact, with high-performance and low weight. Their main use is in the preparation of reagents in small volume tanks. The high rotational speed of the impeller means that they are used in the water treatment sector for dissolution, homogenization, and agitation of mixtures.

SB/SBR/SBN Vertical Stirrers

This type of industrial agitators have a direct motor, guiding tower and support clamp. Their design makes them perfect for agitation in open tanks, for the dispersion of reagents, for the dispersion of powders and for the maintenance of mixtures. They are used in small volume tanks for water treatment and in the chemical, pharmaceutical, food and cosmetic industries.

VAI/VSI/VDI/VSIN Vertical Stirrers

These industrial agitators offer great results. Its reinforced turret system extends the life of the motor, guarantees the robustness of the equipment and provides a high agitation capacity. It is ideal for dissolving solid products, dispersing reagents, agitating dosing tanks and maintaining mixtures.

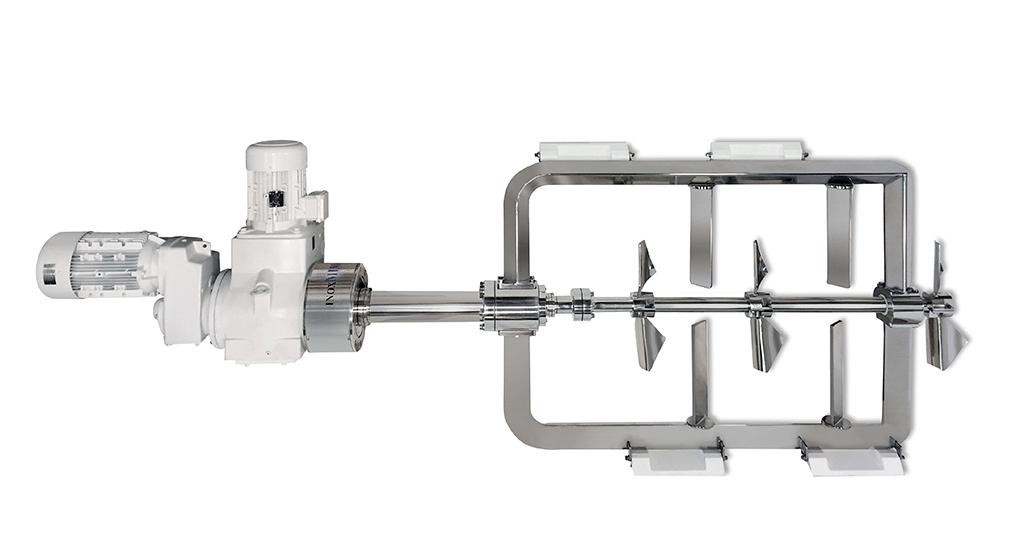

Vertical Stirrers VMD/VMR

These latest generation industrial agitators have a direct motor / motor reducer and a guiding tower. Their variety of impeller elements allows them to work with highly viscous products, with a tendency to form lumps or difficult to mix. They are designed to be used in medium volume tanks, where they efficiently perform dissolutions, product maintenance, reagent mixtures, etc.

IBC Vertical Stirrer

These advanced industrial agitators have a coaxial geared motor. They stand out in the industry for their high-performance and low cost. They have a variety of sizes and types of propellers that provide the equipment with a wide range of speeds to select from.

VCI/VCIN Vertical Stirrers

These industrial agitators are agitators with worm gear reducer. They have a simple and compact design that gives them very low acquisition costs. They are used in many industries, but especially in the dairy sector.

GFL/GFLE Vertical Stirrers

This industrial agitator, thanks to their many drive element configurations, they can be adapted to the requirements of each system. Thus, they stand out due to their wide range of applicability. They are essential equipment in the food, pharmaceutical, cosmetics and chemical industries.

TANDEM Vertical Stirrer

These industrial agitators have a wide range of applicability. They are useful for working with products such as creams, liqueurs, juices, colognes, etc. Their basic operations include the agitation of mixtures, homogenizations, thermal exchanges and chemical reactions.

If you would like to ask us specific questions and resolve possible doubts about the characteristics of our industrial agitators, all you have to do is contact our sales department by sending an e-mail to the address [email protected]. You can also call us by telephone on (+34) 972 58 20 40 or complete our form, so that one of our agents can call you. It’s as simple as that!