Numerous agitation and emulsion solutions for hydrogel or gel sanitiser manufacturers

The COVID-19 crisis has changed society’s consumption habits; products that were previously of virtually no importance are now essential and their production rate has grown exponentially over the last two months. Many companies in various industrial sectors have had to adapt their facilities and production lines in order to produce hydrogel in record time and thus secure their own survival.

At InoxMIM we develop special machinery for hydrogel manufacturers in Spain

A quality hydrogel always has the following three key characteristics: no lumps/solid material; no air bubbles; smooth texture.

Our agitation and mixing department AGITMIM has several machines that can efficiently mix hydrogel components: alcohol, distilled water, glycerin and stabiliser (the most well known brand is Carbopol).

We also have agitators and emulsifiers for producing between 100 and 10,000 litres of sanitizer gel per batch, using either vertical agitation or emulsification, both with EM/EMV equipment and with in-line EML-EMLT systems that are equipped with ATEX motors, should the environment so require.

On the other hand, as experts in industrial machinery who specialise in agitation and mixing equipment, we produce tanks with manual, semi-automatic air agitation and mixing, or those prepared for vacuum if this is required by the customer. We pride ourselves on the fact that we are able to manufacture tailored equipment for each facility and industrial process.

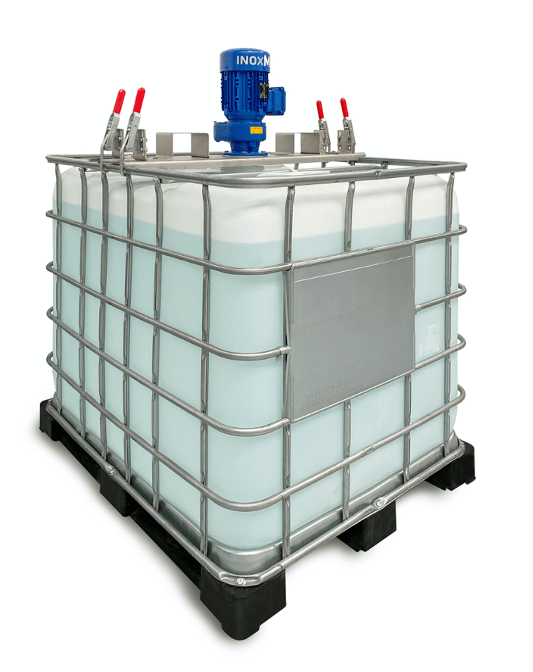

Hydrogel manufacturers: IBC plastic tanks with a capacity of up to 1,000 litres

Depending on the recipe, many hydrogel manufacturers (as well as other product manufacturers) are interested in installing production equipment in IBC plastic tanks with a capacity of up to 1000 litres.

For this reason, InoxMIM has vertical agitation systems with a portable support, and EMLT emulsifiers with an impeller that both facilitates product break down and impels the product in gel solutions with approximately 2000cP viscosity.

Finally, please note that we can also make equipment that is scalable to each customer’s production capacity. We guarantee consistent results, ensuring that the product always turns out the same. By fitting an emulsion system with a high shear capacity, we can drastically reduce production times and improve the product’s final texture at the same time.

Contact us for detailed information about the industrial manufacturing of hydrogel

This type of agitation and mixing equipment is suitable for various applications and can be confusing to understand if the customer doesn’t quite understand the terminology and machinery. Do not hesitate to contact us if you have any questions. You can do this by sending an email [email protected], by calling (+34) 972 58 20 40, or by filling in the form that you can find on this website.