How much electrical expense does a contemporary industrial pumping system entail?

Within the industrial sector, regardless of the area in which we look at it, the energy consumed by pumping systems accounts for the majority of electricity costs. Occasionally, this energy is used efficiently, but in many other cases this is not the case.

It is very common for technicians to be familiar with the control and operation of pumping systems, but less common for them to be familiar with what they need to consider achieving the highest possible degree of energy efficiency.

Pumping systems have played an important role throughout history and especially in modern industrial processes.

They are present in large thermoelectric power plants, in chemical processing companies, in food industries, in large automotive equipment….

On the other hand, they are also very present in our daily life, since, for example, they are commonly used for the supply of water, the evacuation of waste water, the operation of air-conditioning systems…

How is the efficiency of a centrifugal pump calculated?

Efficiency is a ratio between the flow rate delivered, the head or pressure given by the pump, the density of the product and the energy consumed (power absorbed).

The points of maximum efficiency are usually in the central sections of what is known as the efficiency curve, i.e., both on the left (start), where the pump delivers a lot of pressure but little flow — this being the most unstable working point of the whole system — and on the right, where we are approaching the maximum allowed consumption or even over-consumption.

It is important to mention that, if a pump has no back pressure, it will always operate at the maximum possible flow rate, since this is the point on the curve where there is the least resistance.

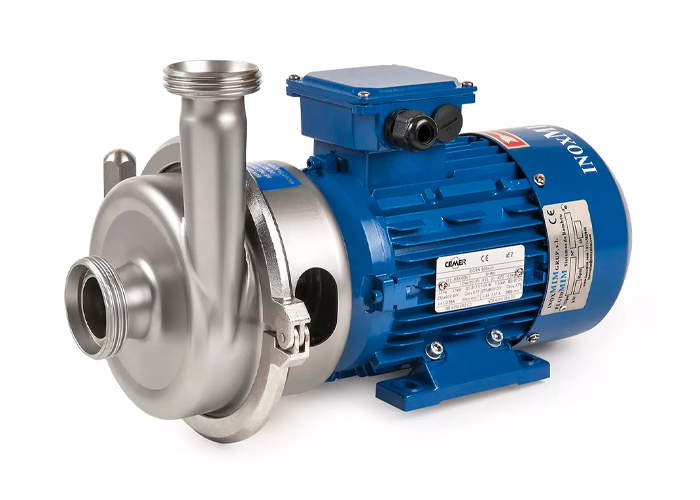

The efficiency value can be calculated for all pumps, but it is much more common for centrifugal pumps, as they are the most widely used pumps in the world.

Related posts:

How to calculate the efficiency in a centrifugal pump: other energy efficiency data

Next, we will delve a little deeper into the terminology and define all the factors involved in pumping systems and centrifugal pumps to make them work efficiently.

These are some of the concepts that must be known and considered getting the best possible performance out of a pumping system. As manufacturers of industrial pumps, we have an extensive catalogue of models and types of pumps, which allow us to cover all the applications of the different industrial sectors we work with. We used to work for the food, pharmaceutical, cosmetics, chemicals, water treatment, etc. sectors, among others.

Request information about our industrial pumps without obligation

Contact us