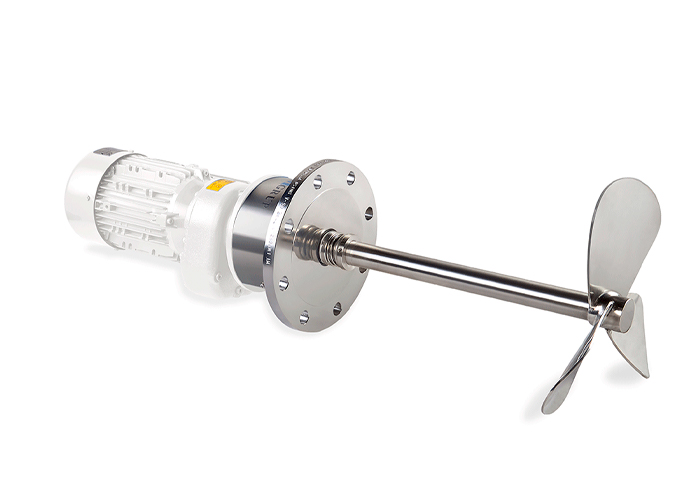

Horizontal industrial agitators, also known as lateral agitators, are characterized by their horizontal position in relation to the base of the tank. At InoxMIM, we design and manufacture lateral agitators suitable for small, medium, and large quantities, ensuring optimal performance.

These types of agitators have a wide range of applications. They are used in industries such as milk processing, where thermal exchanges are required, as well as in industries that involve chemical reactions, suspensions, or mixing of reagents with different densities and natures. They are also used in water treatment industries.

The importance of preventive maintenance for horizontal industrial agitators

The importance of preventive maintenance for horizontal industrial agitators

Performing maintenance on industrial agitators is essential, not only to ensure their optimal operation and extend their lifespan, but also to prevent disruptions in production and reduce costly repair expenses for the company.

That’s why at InoxMIM, we firmly believe that understanding how to carry out maintenance on industrial agitators is crucial for any industry that uses this type of machinery, in order to prevent future issues in the production processes.

The keys to the maintenance of horizontal industrial agitators

The keys to the maintenance of horizontal industrial agitators

At InoxMIM, we have been manufacturing industrial machinery for various sectors and processes for over 25 years. That’s why we understand firsthand how important it is to perform regular preventive maintenance on this type of machines.

Here are the 5 key points to carry out the maintenance of horizontal industrial agitators in your factory:

The horizontal industrial agitators from InoxMIM are robust and low-maintenance

The horizontal industrial agitators from InoxMIM are robust and low-maintenance

In addition to ensuring the preventive maintenance of the agitators, it is very important, when equipping oneself, to ensure that the machines are of high quality and are made with resistant materials. This will result in lower maintenance requirements and a longer lifespan.

This is the case with the lateral agitators from InoxMIM, which are made of stainless steel and provide the best performance with optimal efficiency. Here are our 4 models:

Contact InoxMIM for guidance on the maintenance of our horizontal industrial agitators

Contact InoxMIM for guidance on the maintenance of our horizontal industrial agitators

At InoxMIM, we can provide you with all the necessary information about the features and maintenance of our robust horizontal industrial agitators.

We invite you to contact us, without any obligation, through our contact channels. You can call us at +34 972 58 20 40, send us an email to [email protected], or fill out the contact form on our website. We will be delighted to assist you!