What is the main function of a gear pump for the processing industry?

The main function of a gear pump is to pump and dose liquids that have low indexes (above 200cP) and medium viscosity.

They are very common within the processing industry, specifically in the food and cosmetic sectors for processing margarines, vegetable oils and other liquids or viscous products.

At InoxMIM we have a number of special pump models designed for this process. These include our external gear pumps, the main characteristics and applications of which we explain below.

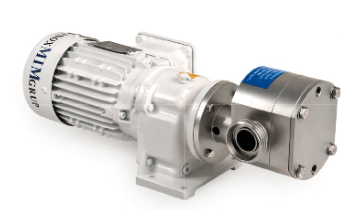

Monobloc external gear pump

FL-ENM external gear pumps are robust and reliable pumps that have been designed to be used for a wide range of applications within the processing industry. They allow and guarantee work to be carried out at precise and fixed flow rates, with excellent results.

They are very common within the food industry and are often used in dosing operations for anchovy paste, chocolates, creams, oils, fats and other products.

How does this external gear pump work?

Product displacement occurs when fluid passes through the spur gear teeth. The driver is driven by the pump shaft (motor), and this forces the other driver to rotate (the idler).

The volume displacement is proportional to the rotation speed and this process provides the necessary equal flow in one direction or the other.

For what kind of application is the external gear pump best suited?

All these conditions make it an ideal model for specific applications like dosing and transferring viscous products, as well as products that have to be treated at a controlled temperature. This is because we can also incorporate a heating chamber in the front part at the customer’s request. This prevents solidification or crystallisation of the resulting product during the process.

Undoubtedly, this is a high-performance gear pump capable of working at very high temperatures. It is very easy to use and makes practically no noise.

It has a long service life and is low maintenance, it is versatile and compact.

It can be complemented with a pressure control device using a pressure switch, a temperature control device that works with probes, a work bench, an iron trolley or a CE control panel. It also works with other connections at the customer’s request: flange, GAS, CLAMP, RJT.

Do not hesitate to request information or a detailed quote from our sales department.

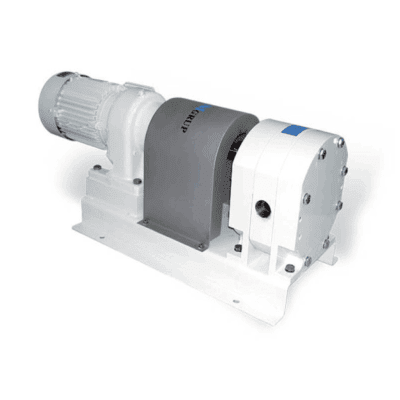

FL-ENC external gear pump

Here we have a robust fixed flow gear pump specially designed to work at high pressures and with flow rates of up to 25m³/h.

It has been designed to offer a high degree of reliability with a technology that guarantees the highest possible efficiency in each process. They are very common both in the food and chemical industries for pumping fats, molasses, oils, starch, cellulose, creams and chocolates …

How does this external gear pump work?

When the fluid passes through its two spur gear teeth, the required flow is generated to guarantee the desired results.

One of the gears is driven by the pump shaft (motor) and rotates the other (the idler), driving the fluid.

For what kind of application is this external gear pump best suited?

At FLUIDMIM we have developed this positive displacement volumetric pump system aimed at the transfer and dosage of viscous products, as well as products that need to be pumped at a high temperature.

They have a long lifespan, are low maintenance and make little noise. They have been designed with the aim of offering today’s production plants a high degree of versatility and reliability, with their compact design and highly resistant manufacturing materials, such as carbon steel F-127, F-5 or Inox AISI 304L and 316L stainless steel.

We can also add a heating chamber with electric, steam or hot water resistances. Finally, at the customer’s request, we can also add all the components mentioned in the previous model.

To contact our sales department and receive personalised advice…

If you would like our sales technicians who are specialised in gear pumps to contact you for a personalised advice, all you need to do is take a few seconds to fill in the following form or send us an email to the address [email protected].

You can also call us at (+34) 972 58 20 40, we will be happy to assist you and resolve any doubts that you may have! This is one of the most important parts of our work.