Widely used for technical emulsions in multiple food, cosmetic and pharmaceutical processes

This model of industrial food and cosmetics mixer has been designed to provide a superior shear strength, resulting in a perfect and high quality emulsion, thanks to its careful mechanical settings, the robustness of all of its components and the high speed of rotation.

Its main characteristics include the fact it has been designed to obtain particles smaller than 0.8 microns, with a rotation speed of 12,000 rpm. It enjoys a mechanical refrigerated double closure, CLAMP connections, a complete draining system or an exterior protection system against environmental oxidation.

It has a sanitary grade finish and is characterized by its high level of hygiene, as well as the technical simplicity of all of its parts.

Its design enables the rotor rotation to reach a speed of up to 33 m/s which, along with its double mechanical seal, guarantees excellent results in high viscosity emulsions.

As if that wasn’t enough, this machine can be complemented by a long list of components that further improve results and enable it to cover more applications within the industry: control panel, frequency inverter, positive feed pump, all types of connections, gaskets in other materials, a trolley and a bench…

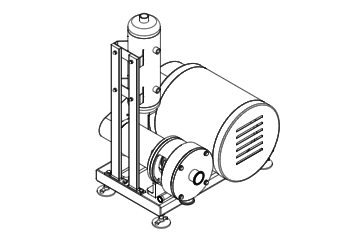

Automatic lifting system designed for our industrial agitation and mixing machines

In this post we wanted to emphasise that we also usually design all types of automatic support and lifting systems, with a high degree of customisation.

This type of components are designed to achieve the maximum degree of homogenisation at all levels of the tank, regardless of its volume, since we can manufacture them for both the mass agitation of high capacity tanks and medium and small tanks.

Depending on the specific requirements of each application or industrial process, we install them with a manual lifting system that works using counterweights, a semi-automatic or automatic system.

These systems reduce the power and the number of impellers required, improving and optimising the agitation process, in addition to requiring hardly any maintenance and cleaning tasks, and offering a long use life to any industrial production plant.

But we must not forget to mention its sanitary finishes or the option of incorporating a control panel, limit switch sensors, programming a remote control… Don’t hesitate to ask us for more information!

Industrial food mixer manufactured according to your product requirements or industrial plant

In our many years in industrial engineering and designing agitation and mixing machinery for the food, cosmetics or pharmaceutical sector, we have made all types of machines and production plants; we even have a testing facility to guarantee the viability of each design, predicting potential errors during the production phase, and easily and quickly identifying whether the machinery will cover the production needs of your factory or company, in terms of performance, final quality of the product or energy efficiency.

So that we can study the type of solution or machine that is most suitable for you or to request a detailed quote, as well as personal advice about any query you may have, you just need to call us by telephone on (+34) 972 58 20 40 or send us an email to [email protected].

If you would prefer one of our technicians to contact you, you just need to spend a few seconds completing this form and we will call you straight away. It’s that easy!

Since its beginnings in 1997, INOXMIM has been strongly linked to the development and manufacture of industrial machinery. The pumping, agitation, mixing and fluid handling systems manufactured have allowed us to satisfy the needs of our customers over the years.

Constant innovation and development allow INOXMIM to provide complete solutions in most processes, thus satisfying the most demanding requirements in the industry.

We are professionals with a long history and experience behind us.