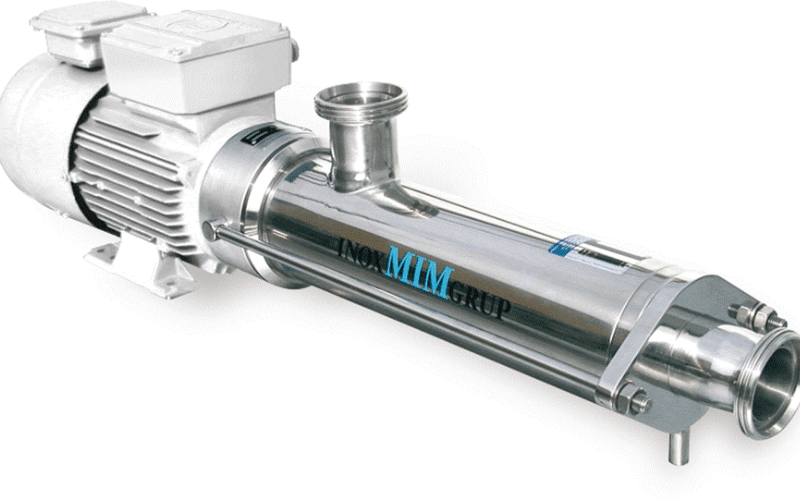

Manufacturers of centrifugal pumps for the process industry

At InoxMIM you will find one of the leading manufacturers of centrifugal pumps with extensive and extensive experience in the R&D of new and improved pumping systems for the food, pharmaceutical, cosmetics and chemical industries.

It is important to note that we have a department specializing in the design, manufacture and development of all types of centrifugal pumps called FLUIDMIM. This department selects the type of centrifugal pump for each transfer or industrial process that guarantees both performance and cost optimization for each application.

We have a wide range of centrifugal pump models. We are one of the leading manufacturers of centrifugal pumps, with high-performance equipment and excellent results.

What are our centrifugal pumps like?

Our centrifugal pumps provide high-performance, top-quality pumping solutions. The different sizes and models we offer adapt to the requirements of each application within the chemical, food, cosmetics or pharmaceutical industry, and can even be custom-designed according to the needs of your production line.

As an experienced manufacturer of machinery for the process industry, we guarantee that the quality of our pumps is ISO 9001 certified.

We always comply with the required guidelines for each product, marked by CE, FDA, ATEX and 3A certification standards, depending on the model and application.

What are the components of a centrifugal pump?

Let’s take centrifugal pumps with helicoidal impellers as an example. They are designed for pumping products containing solid particles and requiring special care in their transfer.

The geometry of the turbine provides a high flow rate that allows the pumping of all types of products in the food industry and, especially, in the wine industry.

What external elements does this centrifugal pump have?

The casing is the outermost part of the centrifugal pump and is made of cast iron for drinking water or bronze. Stainless steel is also used if the liquid is highly corrosive.

The shaft or drive shaft. The shaft is essential in the centrifugal pump. The function of the drive shaft is to transmit the torque it receives from the drive motor during pumping operation. In small monobloc pumps, the shaft of the electric motor extends into the pump and rests on the motor bearings. The shaft is also made of stainless steel.

What internal parts does this centrifugal pump have?

The impeller is used for pumping potable water in small, medium and large flows; centrifugal impellers with radial and semi-axial blades are used. Made of iron, bronze, stainless steel or plastics.

The impellers are assembled separately, inside housings which are cylindrical on the outside, but have special, technically designed profiles on the inside to provide well polished and hydraulically delineated surfaces to minimize the friction they must exhibit when the water flows through. These housings are called bowls.

In addition to supporting the intermediate shaft bearings and all other pump components, the main function of the bowl is to deflect and direct the water flow upwards, thus transforming velocity into pressure.

If you would like to receive personalized advice about our centrifugal pumps…

Visit our section dedicated to centrifugal pumps to see all the models we can install, and contact us if you have any queries. You can finish this by phoning (+34) 972 58 20 40 or email us at [email protected]. You can also take a few seconds to fill in our form, and we will call you right back.

We have an excellent team of technicians and engineers who will help you solve all your pump problems and answer all your questions.