INOXMIM is pleased to demonstrate the differences between the electric pasteuriser and the boiler pasteuriser

This post explains and highlights all the differences between the electric and boiler pasteurisers. Depending on how hot the water generated by the pasteurisation of the milk is, we can differentiate between two types of pasteurisers when talking about HTST pasteurisation via plate heat exchanger.

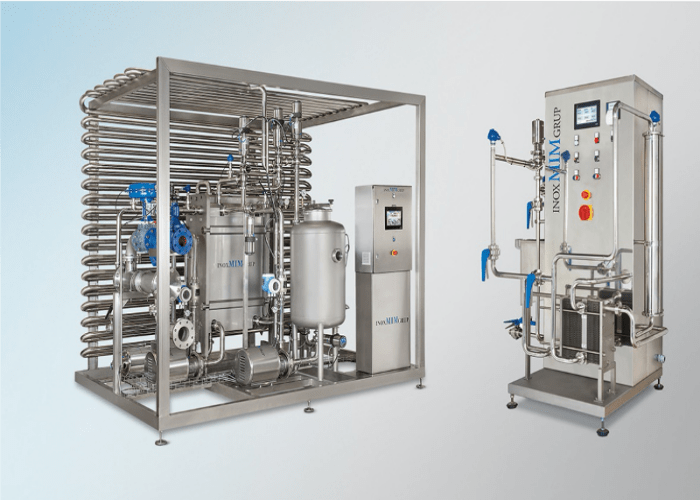

Firstly, we have a conventional system that uses hot water from a boiler or steam generated water, and secondly, a system that uses electrical resistors to produce this fluid.

Modern electric pasteurisers: features and benefits

The first thing we should clarify when looking at electrical pasteurisation systems is that they have a limited capacity, with production levels ranging from 250 L/h to 2000 L/h. They also require more power, and can be equipped with resistors ranging between 10 and 30kW (one or two) in order to reach the desired pasteurisation temperature.

That being said, they also have a number of very compelling advantages. These systems are more economical and compact, ideal for small scale production where there is no need to pasteurise large daily volumes.

Differences between these two milk pasteurisation systems

To understand the differences, let’s have a look at all the specific features of the boiler pasteurisers; they can pasteurise from 500 to 10,000 L/h and are characterised by their larger size and lower electricity consumption, making them more efficient than electric ones. These characteristics facilitate very high daily productions.

Both systems can be semi-automatic or fully automatic if required, although a stand-alone system is more suitable for high production industrial pasteurisation sites .

At InoxMIM we have extensive experience regarding pasteurisation processes

Here at InoxMIM we have always been committed to researching and developing new technologies, particularly in the food sector and in industrial pasteurisation equipment for dairy products. We are well aware that this is a major investment for any company, and there might be some uncertainty regarding the models or their specific applications. Do not hesitate to contact our sales department for more detailed information about any of our equipment or processes. Remember that we have test facilities that allow us to analyse an industrial process’s viability, identifying the most suitable machinery, and minimising errors. You can call us on (+34) 972 58 20 40, send an email to[email protected], or fill out the contact form that can be found on this website.

Es importante poner en valor que también diseñamos y fabricamos todo tipo de equipos de agitación, mezcla y bombeo, pensando en cubrir todas las necesidades y aplicaciones de las distintas industrias con las que solemos trabajar: alimentaria, farmacéutica, química, cosmética… Por otro lado, también solemos fabricar equipos de limpieza CIP de última generación, para una correcta limpieza y desinfección de cualquier planta industrial.

¡Apueste por nosotros y su planta industrial dará un salto hacia el futuro en términos de producción, eficiencia y seguridad laboral!